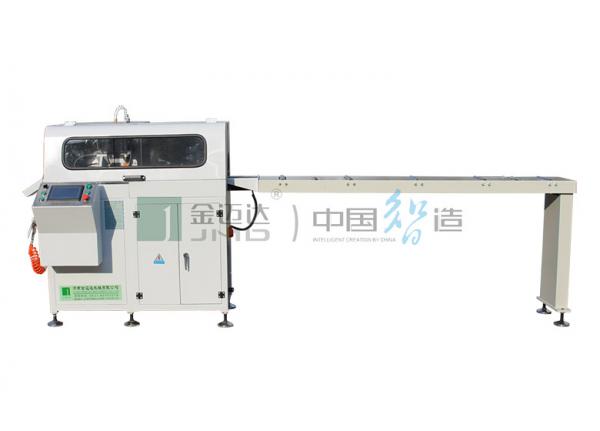

LJG2S-500*6500

Pusat Pemotongan CNC 45 Derajat untuk Pintu dan Jendela Aluminium

16.Bilah: KANEFUSA15.Sekrup pemandu: TBI 14.Rel pemandu linier: HIWIN 13.Perlengkapan & rak: YYC 12.Kabel & kabel: YiChu 11.Komponen pneumatik: AirTAC 10.Komponen listrik tegangan rendah: Schneider 9.Sistem CNC: Schneider 8.Motor yang digerakkan oleh bilah: SEIMEC 7.Trafo insolasi membuatnya sangat aman untuk menggunakan mesin 6.Pengumpul chip blowback pulsa, memulihkan chip pemotongan dengan kebisingan rendah 5.Minimalkan limbah profil aluminium, menghemat biaya. 4.Dilengkapi dengan sistem Schneider CNC dan perangkat lunak optimasi untuk windows. 3.Kecepatan manipulator dikontrol oleh CNC. Sistem kontrol dapat menyimpan data profil.

2.Langkah pemotongan dapat disesuaikan menurut ukuran profil untuk meningkatkan efisiensi pemotongan.